CNC lathes are an invaluable piece of machinery for any modern workshop, but getting the most out of them means investing in the right tool holders. An ideal tool holder can meet your needs and requirements while staying within your budget. In this blog post, we’ll explore what you need to know about tool holders and how to choose right tool holders for your CNC machines.

What Are Tool Holders and Why Are They Important?

A tool holder is a device used to secure a cutting tool in a machine’s spindle. They are used to mount cutting tools such as end mills, drills, or reamers into the spindle to be used precisely and accurately while machining material.

The importance of having a quality tool holder cannot be overstated; it should meet all performance requirements and provide a secure fit while offering flexibility if needed.

Types of Tool Holders Available on the Market

Choosing tool holders for your CNC lathe can be confusing, so we’ll try to break it down. First, there are several types of tool holders that you can use for your lathe.

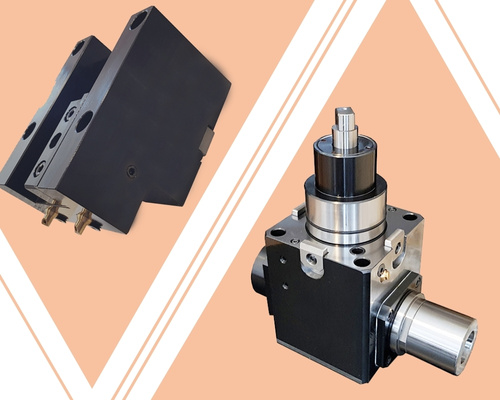

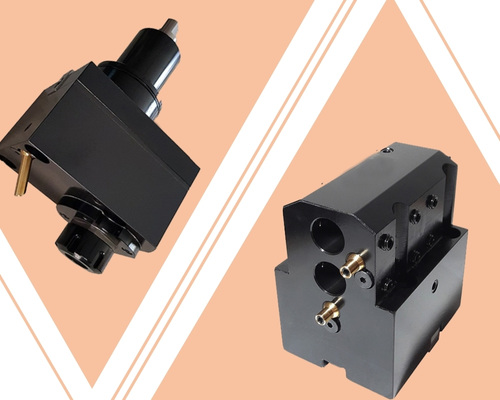

These include static tool holders and live tool holders, each with its own advantages and disadvantages. Each type of tool block comes in different specifications and sizes.

Static tool holders

Static tool holders are an important part of machining as they provide a secure and consistent way of holding the cutting tool. This helps to ensure that the accuracy and repeatability of the machined parts are high, regardless of whether manual or CNC machines are being used.

Static tool holders come in many forms, such as boring bar holders, facing holders, OD holders, and cut-off holders. Each type has its own features, which make it suitable for different applications.

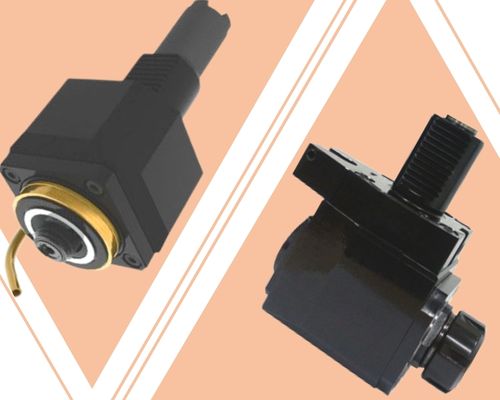

Live tool holders

Live tool holders fit onto the spindle of a CNC machine, allowing for rotary motion and axial movement in all three directions (x, y, and z). This makes them ideal for complex applications such as threading and hole-making, where two or more cutters must be used simultaneously.

The holder can also accommodate various cutting inserts, providing size, shape, and material type flexibility. In addition, they can be adjusted to different speeds while maintaining accuracy and repeatability over long runs.

Tool holders of different machine types

Doosan tool holders

Doosan tool holders are essential for ensuring that precision tools work properly on a Doosan CNC machine. They allow the machine to securely and precisely control and hold the cutting tool, facilitating machining.

They come in various types, each designed to work with a specific type of tooling. For example, ER collets fit tools with an internal diameter of up to 0.250″. High-precision drill chucks accommodate drills up to 0.375″ in diameter.

Hyundai WIA tool holders

The tool rest required for a particular CNC machine is different. You must choose the right holder for your CNC machine and ensure it is compatible with the spindle interface. So check out our Hyundai WIA tool holders and find the one that best suits your needs.

Mazak tool holders

Some tool holders are designed specifically for specific machine types and can vary in size, shape, and material.

Mazak tool holders offer additional features designed specifically for Mazak CNC machines, such as taper length adjustment capabilities or tool holder retention systems.

Haas tool holders

Haas tool holders are widely suitable for CNC lathe machinery to ensure the accurate and precise cutting of materials. The tool holder fits securely onto a lathe chuck or chuck and provides a stable location for the workpiece during rotation.

Considerations Before Buying Tool Holders For CNC Machines

Before buying a new tool holder for your CNC lathe, there are several factors you should take into consideration:

- Performance Requirements: First and foremost, consider your performance requirements for the tool holder. It ensures that it meets those requirements before making a purchase.

- Size/Weight: Next, consider the size and weight of your lathe and the desired tool holder. It makes sure they are compatible before purchasing.

- Cost: Cost is always important when purchasing new equipment; determine which options fit your budget while still providing good performance.

- Additional Features: Some types of holders offer features such as quick-change systems or online support; decide whether these features would be beneficial before deciding.

- Safety: Finally, safety is paramount when dealing with milling equipment. It ensures that all safety aspects are considered before selecting (such as using guards and other protections).

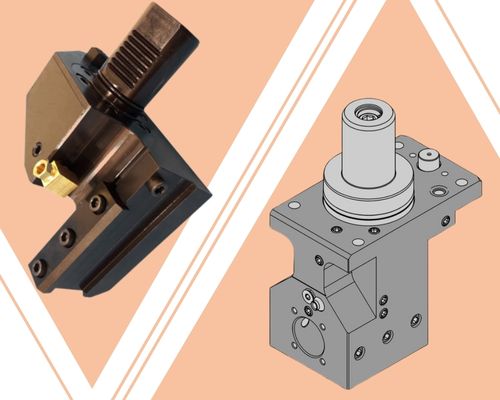

Our manufacturing capability for custom tool holders

We have an extensive range of custom tool holder capabilities to meet the needs of any machine.

Our manufacturing process is based on quality and efficiency, delivering high-precision tool holders that are durable and reliable. We can manufacture various tool holders using state-of-the-art CNC machines and cutting-edge technology.

We also offer engineering services such as CAD design to ensure accuracy and repeatability for custom projects.

Conclusion

Choosing the right tool holder for your CNC lathe takes careful consideration. Still, it is well worth taking time over – it could mean improved performance from your machine without compromising on price or features.

Research different types available on the market, consider size, weight, performance capabilities cost, then evaluate potential safety risks before deciding which one will work best in your particular circumstance.

Don’t hesitate to ask for professional advice if required – after all, investing in quality equipment often pays dividends in peace of mind.

What are the types of static tool holders?

When choosing a tool holder for a machining process, it is important to understand the two main types of fixed tool holders available: VDI and BMT.

VDI (Verein Deutscher Ingenieure) holders have standardized interfaces that enable quick changeover times and provide high accuracy and repeatability.

BMT (British Machine Tool) holders, while not as accurate or repeatable as VDI, are faster to set up and offer more flexibility when it comes to different applications.

VDI tool holders come in several styles, including shrink fit, hydraulic clamping, and Weldon clamping. All three styles use a modular system that allows for an easy exchange of tools with minimal setup time.

With VDI tool holders, you can be confident in the accuracy of your machining operations since each holder has precise tolerances that ensure compatibility between the various components.